Potso ea hore na pompo ea hydraulic e ka hlahisa khatello ke ea bohlokoa ho utloisisa mosebetsi oa mantlha oa tsamaiso ea hydraulic. Ha e le hantle, lipompo tsa hydraulic li phetha karolo ea bohlokoa ho fetola matla a mechine hore e be matla a hydraulic, kahoo a baka khatello ka har'a mokelikeli. Lisebelisoa tsena li etselitsoe ho monya mokelikeli oa hydraulic le ho sebelisa matla ho o sutumetsa ka har'a sistimi, ho theha khatello e matlafatsang mefuta e fapaneng ea mechini le lisebelisoa. Ho sa tsotellehe hore na ho sebelisoa pompo ea piston e khutlisetsang kapa pompo ea gear e itšetlehileng ka likere tse potolohang, lipompo tsa hydraulic li etselitsoe ho hlahisa matla a hlokahalang bakeng sa ts'ebetso e nepahetseng ea tsamaiso ea haeteroliki.

1. Molao-motheo o sebetsang oa pompo ea hydraulic

2. Mofuta oa pompo ea hydraulic e hlahisang khatello

3. Lintlha tse amang khatello ea khatello ho li-hydraulic systems

1. Molao-motheo o sebetsang oa pompo ea hydraulic

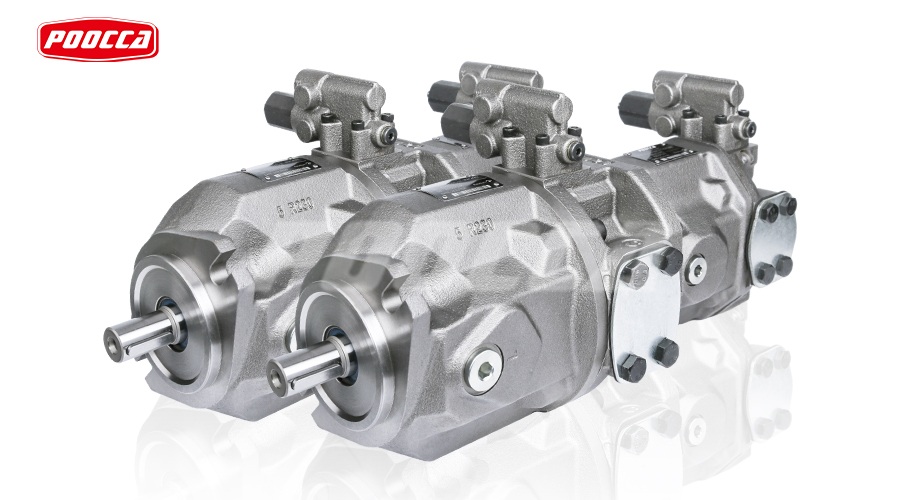

Pompo ea hydraulic ke karolo ea bohlokoa tsamaisong ea hydraulic, mosebetsi oa eona oa bohlokoa ke ho hlahisa khatello ea ho khanna mokelikeli ka tsamaiso. Ho feto-fetoha ha bona ho ba lumella ho matlafatsa mefuta e mengata ea mechine le lisebelisoa, ba bapala karolo ea bohlokoa liindastering tse kang ho etsa thepa, kaho le lipalangoang. Mona re hlahloba lipompo tse peli tse tloaelehileng tsa hydraulic tse sebetsang hantle ho hlahisa khatello:

1. Pompo ea piston:

Lipompo tsa piston li tsebahala haholo ka bokhoni ba tsona ba ho hlahisa khatello e phahameng lits'ebetsong tsa hydraulic. Ba sebetsa ka molao-motheo oa ho khutlisa, moo piston e eang pele le morao ka har'a cylinder. Ha piston e hula, ho etsoa vacuum e hulang oli ea hydraulic ka har'a silindara. Joale, ha piston e ntse e atoloha, e hatella mokelikeli, o o qobella ho pholletsa le pompo le ho kena tsamaisong ea haeteroliki.

E 'ngoe ea melemo ea mantlha ea lipompo tsa piston ke bokhoni ba tsona ba ho hlahisa maemo a lekaneng a khatello, e leng se etsang hore li tšoanelehe bakeng sa lits'ebetso tse hlokang matla a phahameng, joalo ka mechini e boima ea liindasteri le likhatiso tsa hydraulic. Ho phaella moo, lipompo tsa piston tse feto-fetohang li ka fetola phallo ea phallo ho laola maemo a khatello ho latela litlhoko tse khethehileng tsa kopo.

2. Pompo ea lisebelisoa:

Lipompo tsa gear ke mofuta o mong o tummeng oa pompo ea hydraulic e tsejoang ka ho ba bonolo le ho tšepahala. Li na le lisebelisoa tse peli tsa meshing - sesebelisoa sa ho khanna le se tsamaisoang - se kentsoeng ka har'a mokotla oa pompo. Ha likere li ntse li bilika, li etsa liphaposi tse hulang mokelikeli oa haeteroliki sebakeng sa pompo. Ho potoloha ho etsa hore mokelikeli o kene ka har'a sephutheloana, e leng se etsang hore ho be le khatello e hlokahalang bakeng sa ho sebelisa hydraulic system.

Le hoja lipompo tsa gear li ka 'na tsa se ke tsa finyella maemo a tšoanang a khatello e phahameng joaloka lipompo tsa piston, li sebetsa hantle ka likopo tse hlokang ho phalla ho tsitsitseng le ho tsitsitseng ha mokelikeli. Moqapi oa eona o kopanetsoeng, theko e tlaase le tlhokomelo e fokolang e etsa hore e tšoanelehe bakeng sa mefuta e fapa-fapaneng ea liindasteri, ho kenyelletsa le lisebelisoa tsa ho sebetsana le thepa, tsamaiso ea tsamaiso le lisebelisoa tsa matla a hydraulic.

Khetho ea pompo ea piston le pompo ea gear e itšetlehile ka litlhoko tse khethehileng tsa tsamaiso ea hydraulic. Lipompompo tsa piston li ratoa lits'ebetsong tse hlokang khatello e phahameng le phallo e fapaneng, ha lipompo tsa gear li nkoa e le tsa bohlokoa bakeng sa ho nolofatsa ha tsona, ho tšepahala le ho sebetsa ka litšenyehelo ha li sebelisoa moo phallo e tsoelang pele le e ts'oanang e leng ea bohlokoa. Tsoelo-pele e tsoelang pele ea theknoloji ea pompo ea hydraulic e ntse e tsoela pele ho ntlafatsa ts'ebetso ea likarolo tsena tsa bohlokoa, ho khanna katleho le mekhoa e mecha ho pholletsa le liindasteri tse fapaneng.

2. Mofuta oa pompo ea hydraulic e hlahisang khatello

Pompo ea hydraulic ke sesebelisoa sa ho fetola matla se fetolang matla a mochini hore e be matla a khatello ea metsi. Molao-motheo oa eona oa ho sebetsa ke ho sebelisa phetoho ea molumo o koetsoeng ho tsamaisa mokelikeli, le ho itšetleha ka molao-motheo oa phetoho ea molumo ho finyella mosebetsi. Lipompo tsa Hydraulic kaofela li sebetsa ho latela molao-motheo oa phetoho ea molumo oa tiiso, kahoo li boetse li bitsoa lipompo tsa hydraulic tse ntle.

Lipompo tsa Hydraulic li arotsoe ka mofuta oa gear, mofuta oa vane, mofuta oa plunger le mefuta e meng ho latela sebopeho sa bona. E mong le e mong o na le litšobotsi tsa hae, empa a sebetsa ka molao-motheo o tšoanang. Phallo ea phallo ea pompo ea hydraulic e ka fetoloa ha ho hlokahala ho fihlela litlhoko tsa maemo a fapaneng a ts'ebetso.

Ha pompo ea hydraulic e sebetsa, e potoloha tlas'a ho khanna ha mochine oa pele, ho etsa hore molumo o sebetsang o tsoele pele ho fetoha, kahoo o etsa mokhoa oa ho hula oli le ho tsoa ha oli. Sekhahla sa phallo ea pompo ea hydraulic e itšetlehile ka boleng ba phetoho ea molumo oa kamore ea ho sebetsa le palo ea liphetoho ka nako ea yuniti, 'me ha e amane le khatello ea ho sebetsa le maemo a liphaephe tsa ho hula le ho ntša metsi.

3. Lintlha tse amang khatello ea khatello ho li-hydraulic systems

Moloko oa khatello ea tsamaiso ea hydraulic e angoa ke lintlha tse ngata. Mona ke a mang a mabaka a mantlha:

**Boholo ba moroalo: Ha mojaro o moholo oa sistimi ea hydraulic, o phahamisa khatello e lokelang ho hlahisoa. Mojaro e ka ba boima ba motsoako oa mochini, khohlano, kapa khanyetso e 'ngoe.

**Viscosity ea oli: Viscosity ea oli e ama sekhahla sa phallo ea eona le litšobotsi tsa phallo liphaepheng. Oli e phahameng ea viscosity e tla fokotsa lebelo la ho phalla le ho eketsa tahlehelo ea khatello, ha oli e tlaase ea viscosity e tla potlakisa lebelo la ho phalla le ho fokotsa tahlehelo ea khatello.

**Bolelele ba Pipe le Diameter: Bolelele le bophara ba phala bo ama sebaka le ho phalla ha oli tsamaisong. Liphaephe tse telele le li-diameter tse nyane li eketsa tahlehelo ea khatello, kahoo li fokotsa khatello tsamaisong.

**Li-valve le lisebelisoa: Li-valve le lisebelisoa tse ling (tse kang li-elbows, manonyeletso, joalo-joalo) li ka thibela ho phalla ha oli, ho baka tahlehelo e eketsehileng ea khatello. Ka hona, ha u khetha le ho sebelisa likarolo tsena, tlhokomelo e lokela ho lefshoa ho phello ea bona ts'ebetsong ea tsamaiso.

** Ho lutla: Ho lutla hofe kapa hofe ho sistimi ho tla fokotsa khatello e teng kaha ho lutla ho baka tahlehelo ea oli le ho fokotsa khatello ea sistimi. Ka hona, ho bohlokoa ho hlahloba le ho boloka sistimi ea hau khafetsa ho thibela ho lutla.

** Liphetoho tsa mocheso: Liphetoho tsa mocheso li ka ama viscosity le litšobotsi tsa phallo ea oli. Lithempereichara tse phahameng li eketsa viscosity ea oli, e leng se eketsang tahlehelo ea khatello; ha mocheso o tlase o fokotsa oli, e leng ho fokotsang tahlehelo ea khatello. Ka hona, liphello tsa mocheso li lokela ho nkoa ha ho etsoa le ho sebetsa litsamaiso tsa hydraulic.

** Ts'ebetso ea Pompo: Pompo ea hydraulic ke karolo ea bohlokoa tsamaisong e hlahisang khatello. Ts'ebetso ea pompo (e kang ho falla, sebaka sa khatello ea ts'ebetso, joalo-joalo) e ama ka ho toba matla a ho hlahisa khatello ea tsamaiso. Ho bohlokoa ho khetha pompo e nepahetseng bakeng sa litlhoko tsa sistimi ea hau ho netefatsa ts'ebetso e nepahetseng ea sistimi.

** Li-accumulators le Li-valve tsa Taolo ea Khatello: Li-accumulators le li-valve tsa ho laola khatello li ka sebelisoa ho laola maemo a khatello tsamaisong. Ka ho lokisa likarolo tsena, taolo e sebetsang le tsamaiso ea khatello ea tsamaiso e ka finyelloa.

Moloko oa khatello ea tsamaiso ea hydraulic e angoa ke lintlha tse ngata. E le ho netefatsa ts'ebetso e tloaelehileng le ts'ebetso e nepahetseng ea sistimi, baqapi le basebelisi ba tlameha ho nahana ka lintlha tsena le ho nka mehato e ts'oanang bakeng sa ts'ebetso le taolo.

Karabo e hlakileng ea potso e hlahisitsoeng qalong ke e - pompo ea hydraulic ka sebele ke sesebelisoa se ka sehloohong sa ho hlahisa khatello tsamaisong ea hydraulic. Karolo ea bona ea ho fetola matla a mochini hore e be matla a haeteroliki e bohlokoa liindastering tse ngata, ho tloha ho tsa tlhahiso le kaho ho isa sebakeng sa sefofane le likoloi. Khatelo-pele e tsoelang pele ea theknoloji ea pompo ea hydraulic e tsoela pele ho ntlafatsa le ho ntlafatsa tlhahiso ea khatello, e leng se hlahisang mekhoa e metle le e tsitsitseng ea hydraulic. Ha indasteri e ntse e tsoela pele, lipompo tsa haeteroliki li lula li sa sisinyehe ka bohlokoa ba tsona ho fana ka matla a hlokahalang bakeng sa lits'ebetso tse se nang palo, li totobatsa boemo ba tsona e le karolo ea bohlokoa mecheng ea lefatše la sejoale-joale.

Nako ea poso: Dec-06-2023