Indastering ea sejoale-joale ea hydraulic, ho khetha mofuta o nepahetseng oa pompo ho ka ama ts'ebetso ea sistimi, ts'ebeliso ea matla le nako ea bophelo ka kakaretso. Lipompo tse sebelisoang ka ho fetesisa tse ntle ke lipompo tsa vane lelipompo tsa gear. Le hoja ka bobeli e le tsa bohlokoa tsamaisong ea matla a mokelikeli, li sebetsa ka tsela e fapaneng 'me li loketse lits'ebetso tse fapaneng.

Sengoliloeng sena se ngotsoe ke Poocca Hydraulic ho fana ka papiso ea litsebi tsa vane le lipompo tsa gear ho thusa baenjiniere, batsamaisi ba rekang, le li-integrator tsa hydraulic system ho etsa liqeto tse nepahetseng tsa ho reka.

1. Molao-motheo o Sebetsang: Kamoo Li Sebetsang Kateng

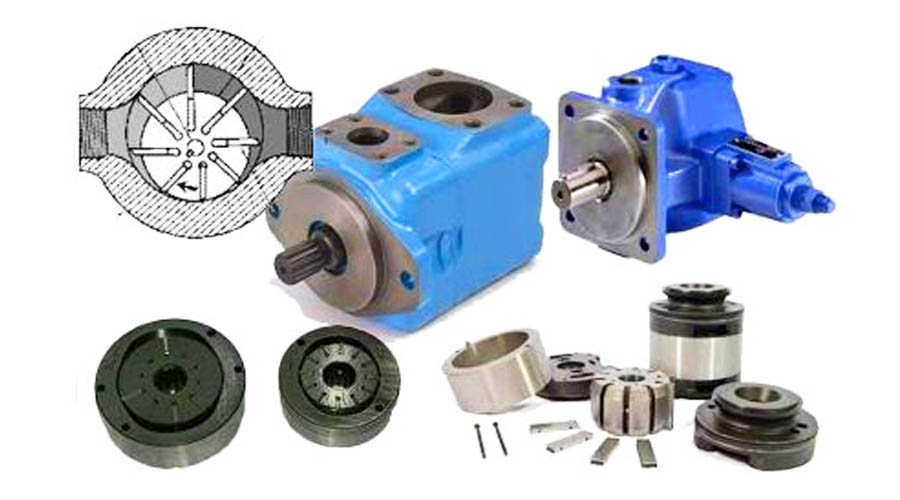

Lipompo tsa Vane tsa Hydraulic:

Lipompo tsa Vane li sebetsa ka rotor e potolohang ka har'a sekoti. Rotor e na le li-vane tse ngata tse thellang tse tsamaisoang ka ntle ka matla a centrifugal 'me li hatelloa khahlanong le ntlo ea pompo. Ha rotor e fetoha, molumo o pakeng tsa li-vanes o fetoha, o lumella pompo hore e hule le ho tsoa mokelikeli.

Melemo ea Moqapi: Li-vane tse thellang li lula li kopana le ntlo ea pompo, e leng se etsang hore ho be le phallo e bonolo ea mokelikeli le ho fokotseha ho fokolang.

Lipompo tsa Gear tsa Hydraulic:

Lipompo tsa gear hangata li fumaneha ka mefuta e 'meli: lipompo tsa lisebelisoa tsa kantle le lipompo tsa lisebelisoa tsa kahare. Lipompo tsa lisebelisoa tsa kantle li sebelisa likere tse peli tsa meshing ho potoloha ho etsa mokelikeli le ho fana ka mokelikeli. Lipompo tsa ka hare tsa lisebelisoa li sebelisa lisebelisoa tse potolohang ka hare ho e 'ngoe, li sebelisa li-washer tse nang le sebōpeho sa crescent ho tsamaisa mokelikeli.

2. Sebopeho le ho rarahana

StandardPompo e nyanePompo ea lisebelisoa

Sebopeho sa ka hare se rarahane ho feta (li-vane tse thellang, li-rotor, li-cam rings) Tse bonolo (li-meshing gears feela)

Tlhokomelo e Hloka kopano e nepahetseng haholoanyane le tlhahlobo ea kamehla ea li-vane Ho bonolo ho e hlokomela le ho e kopanya

Boholo le boima ba 'mele Ka tloaelo e kholoanyane ka lebaka la sebopeho sa mochini o ka hare O kopane ebile o bobebe

Lintlha tsa bohlokoa: Lipompo tsa Vane li rarahane ho feta, empa li sebetsa hantle ka mekhoa e nepahetseng. Lipompo tsa gear li na le likarolo tse fokolang tse tsamaeang, ho tšepahala ha nako e telele le ho boloka chelete.

3. Khatello ea Hydraulic le litšobotsi tsa phallo

Lipompompo tsa Vanilla:

Khatello e kholo: Ka tloaelo ho fihla ho 210 bar (3000 psi)

Phallo ea phallo: Ts'ebetso e tlase haholo, e khutsitseng

Taolo ea phallo: E laoloa haholo, e loketse meralo e fapaneng ea phallo

Lipompo tsa Gear:

Khatello e kholo: E ka ba 250 bar (3600 psi), ho latela mohlala le lebitso

Flow pulsation: Pulsation e kholo ha e bapisoa le lipompo tsa vane

Taolo ea phallo: Karabelo e liehang, e sebelisoang haholo lits'ebetsong tsa bongata

Temohisiso: Lipompo tsa Vane ke khetho ea pele bakeng sa lits'ebetso tse hlokang phallo e boreleli le lerata le tlase, joalo ka lisebelisoa tsa mochini oa CNC, mochini oa ho bopa ente kapa li-hydraulic system tsa kahare. Bakeng sa likoloi tsa indasteri kapa lisebelisoa tsa kaho, lipompo tsa gear li thata ebile li na le khatello e phahameng ea khatello.Iteanye le rona

4. Lipompo tsa hydraulic vane lipompo tsa Gear pompo e sebetsang hantle le ho boloka matla

Ho sebetsa hantle ke sesupo sa bohlokoa bakeng sa litsamaiso tsa hydraulic, haholo kajeno ha liindasteri tsohle li ntse li phehella taolo e ntle ea matla le nts'etsopele e tsitsitseng.

Bokhoni ba pompo ea Vanilla: Ka kakaretso e na le ts'ebetso e phahameng ea volumetric le ts'ebetso ea mochini, haholo lipompong tse fapaneng tsa phallo ea batho.

Katleho ea Pompo ea Gear: Ho sebetsa hantle ha likhatello tse phahameng, empa ho ka fokotseha ka lebelo le tlase kapa lipotoloho tse telele ka lebaka la ho lutla ka hare.

Ka ho phahama ha litharollo tsa hydraulic tse sebetsang hantle, lipompo tsa vane li ntse li sebelisoa haholo lits'ebetsong tse hlokang phallo e fapaneng ntle le tlhoko ea li-inverters kapa taolo ea lebelo la enjene.

5. Litšenyehelo khahlanong le Papiso ea Kopo

Factor Vane Pump Gear Pump

Litšenyehelo tsa Pele li Phahameng ka Tlase

Theko ea nako e telele e Theohile ka lebaka la ts'ebetso e phahameng le linako tse telele tsa tlhokomelo Litšenyehelo tse phahameng tlas'a maemo a feteletseng

Lits'ebetso tse Tloaelehileng Mechini ea polasetiki, likhatiso, li-lifti Ho lahla literaka, literekere, lifti tsa indasteri

Mohlala, lipompo tsa Poocca vane hangata li khethoa ke bareki bakeng sa ho etsa ente, metallurgy e nepahetseng, le mehala ea kopano e ikemetseng.

Ka hlakoreng le leng,Lipompo tsa gear tsa Poocca(ho kenyeletsoa le mehlala e ka fapanyetsanoang le Parker, Rexroth, le Shimadzu) li romelloa linaheng tse ling bakeng sa likoloi tsa kaho, literaka tsa ho lahla, le mechine ea merafo bakeng sa ho tšepahala le ho boloka litšenyehelo.

6. Boemo ba Lerata le Vibration

Ena ke ntho e atisang ho hlokomolohuoa, empa ke ea bohlokoa libakeng tseo matšeliso a basebetsi, melao ea litoropo, kapa botsitso ba mochini e leng tsona tse tlang pele.

Lipompo tsa Vane li sebetsa hantle haholoanyane, ka ho thothomela ho tlase haholo le maemo a lerata (tlase ho 60 dBA).

Lipompo tsa gear li hlahisa lerata le eketsehileng ka lebaka la meshing ea likere, haholo-holo ka likhatello tse phahameng le lebelo.

Keletso: Sebelisa lipompo tsa vanene libakeng tseo ho leng lerata, joalo ka lilaboratori, lipetlele kapa limela tsa ka tlung.

7. Lubrication le ho lumellana ha mokelikeli

Lipompompo tsa Hydraulic vane: E hloka oli e hloekileng ea hydraulic ho thibela ho roala ha vane. Lipompo tsa Vane li na le maikutlo a mangata ho silafatsoa.

Lipompo tsa Gear: E khona ho sebetsana le viscosity e phahameng kapa maro a silafalitsoeng ho feta, a loketseng ts'ebetso ea kantle kapa e boima.

Lipompo tsa gear li ka nka nako e telele haeba u sebelisa ho sefa hantle kapa maro a phahameng a viscosity.

8. Nako ea bophelo le tlhokomelo

Le ha lipompo ka bobeli li ka tšoarella lilemo tse ngata, li na le linako tse fapaneng tsa tlhokomelo:

Lipompo tsa Vane: Li ka hloka tlhahlobo / phetolo ea li-vane khafetsa. Leha ho le joalo, mefuta ea sejoale-joale (joalo ka Poocca variable displacement vane pompo) e na le li-vane tse itefellang tse lelefatsang bophelo.

Lipompo tsa Gear: Ho bonolo ho li hlokomela, empa ho roala meno a gear ha nako e ntse e ea ho ka fokotsa ts'ebetso, haholo ha li sebelisoa ka maro a abrasive.

Ho sa tsotelehe mofuta oa pompo, ho khetha kemiso e nepahetseng ea tlhoekiso le kemiso ea tlhokomelo e ka lelefatsa bophelo ba ts'ebeletso.

Kakaretso ea Papiso ea ho Qetela

Likarolo tsa Vane Pump Gear Pump

Ho rarahana Ho Holimo Tlase

Precision & Control Excellent Medium

Boemo ba Lerata Tlase Mahareng-Hodimo

Khatello ea Boemo Bohareng bo Phahameng

Litšenyehelo Litsenyehelo tse phahameng tsa pele, bophelo bo khuts'oane ba ts'ebeletso Theko e tlase ea pele, bophelo bo bolelele ba ts'ebeletso

Bohloeki ba Mokelikeli bo Hloka maro a hloekileng Ho mamella tšilafalo haholoanyane

Indasteri e Tloaelehileng e Sebelisa Lisebelisoa tsa Mochini, Liroboto, Likoloi tsa Temo, Lipalangoang, Kaho

Qetello: U Lokela ho Khetha Efe?

Khetho pakeng tsa vane le lipompo tsa gear e itšetlehile haholo ka kopo ea hau:

Haeba sistimi ea hau e hloka lerata le tlase, taolo e nepahetseng, le ho boloka matla, khetha pompo ea vane.

Haeba o hloka tharollo e thata, e theko e tlaase e khonang ho sebetsana le maro a thata le ho sebetsa libakeng tse thata, khetha pompo ea gear.

Haeba o sa tiisehe, ikopanye le moetsi ea tšeptjoang oa haeteroliki joaloka Poocca, ea fanang ka tharollo ea pompo ea li-vane le ea gear ka tšehetso ea ho itlhophisa, tšehetso ea tekheniki, le thomello ea lefatše ka potlako.

9.Hobaneng ho Khetha Poocca Hydraulic Manufacturer?

Joaloka morekisi ea ka sehloohong 'marakeng oa lefatše oa hydraulic, Poocca e fana ka:

Mefuta e felletseng ea lipompo tsa vane le lipompo tsa gear, tse tsamaellanang le lihlahisoa tse etellang pele

Likhetho tsa tlhahiso ea OEM le ODM

Baenjiniere ba hloahloa ba thekiso ho thusa ka khetho le ho e etsa

Litheko tse fumanehang, waranti ea likhoeli tse 12

E fumaneha, ho tsamaisoa ka potlako

Ikopanye le Poocca hona joale

E re re u thuse ho khetha pompo e ntle ka ho fetisisa bakeng sa morero oa hau.

Nako ea poso: Jun-19-2025